Underpads’ materials are crucial for their performance, comfort, and effectiveness. Here are the common materials used in underpads and their characteristics:

1. Top Sheet Materials

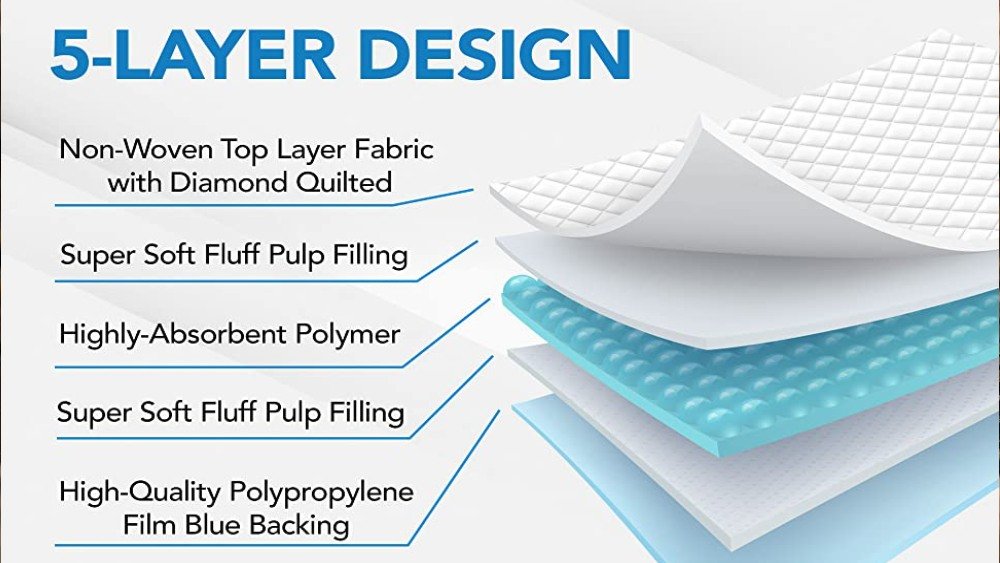

Non-Woven Fabric: Non-woven fabric is a common material used for the top sheet of underpads. It is soft, breathable, and provides a comfortable feel while effectively absorbing urine. The non-woven fabric also has quick moisture-wicking properties that help keep the skin dry, reducing discomfort.

Fluff Pulp: Some underpads use a fluff pulp layer, which enhances absorbency and breathability, further improving comfort.

2. Absorbent Core

Super Absorbent Polymer (SAP): Super absorbent polymer is a common absorbent material used in underpads. It quickly absorbs liquid and locks it inside, preventing leakage. SAP can absorb a large amount of urine and convert it into a gel-like state, providing long-lasting dryness.

Fluff Pulp and Paper Pulp Blend: This combination of materials is used in the absorbent core of some underpads. It enhances absorbency and helps distribute urine evenly. The paper pulp layer helps maintain uniform absorption, while fluff pulp keeps the surface dry.

3. Backsheet (Waterproof Layer)

Polyethylene (PE) Film: Polyethylene film is commonly used in the backsheet of underpads as a waterproof material. It effectively prevents urine leakage, protecting bed sheets or other surfaces from contamination. This material ensures that urine is contained, while still maintaining the softness of the pad.

Heat-Sealed Non-Woven Fabric: Some high-quality underpads also use heat-sealed non-woven fabric. This material is more breathable than polyethylene and offers better comfort and skin protection.

4. Additional Functional Layers

Fragrance Layer: Some underpads feature a fragrance or deodorizing layer to help reduce odors and enhance comfort. This layer is typically thin and does not interfere with the breathability or absorbency of the pad.

Antibacterial Coating: Some underpads are designed with antibacterial coatings to prevent bacterial growth, especially for patients who are bedridden or suffer from incontinence. This helps ensure a hygienic environment for the user.

5. Softness and Comfort

Non-Woven Inner Lining: Some underpads use soft non-woven fabric for the inner lining to ensure that the user’s skin is not irritated. Comfort is especially important for long-term users, as it helps avoid discomfort and skin issues.

Breathability Design: Some underpads are specifically designed with breathable materials to allow the skin to breathe, reducing heat buildup and preventing skin damage and diaper rash.

Conclusion

The material design and selection of underpads directly affect their absorbency, waterproofing, comfort, and skin protection. Choosing the right materials ensures that underpads can effectively prevent leakage while providing maximum comfort, especially for long-term care, elderly care, and bedridden patients.